2008 - 2009 taurus 3.5L Torque Specs

2009 taurus Rear End Torque Specs

Click the area you are looking for!

Taurus 3.5L Repair Information

Taurus 3.5L Rear End Repair Information

Here you can find information regarding repairs to the Taurus rear end system. These repairs include the rear control arms installation, the rear swaybar information and bolt torque specs, the rear diff fluid change procedures, and the rear end watts system installation. All of these repairs and procedures include in depth details on how to perform the replacement and or repair. They also contain all the detailed torque specs needed for each bolt involved in the repair.

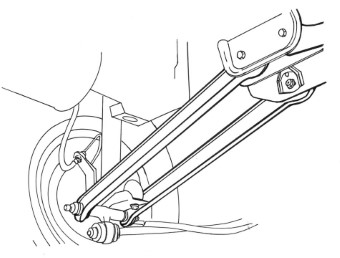

Rear Control Arm Installation

Taurus Rear Arm Torque Specs : 75 ft-lbs

Rear Swaybar Installation

Taurus Swaybar to Strut Torque Spec : 10 ft-lbs

Taurus Swaybar to Frame Torque Specs : 30 ft-lbs

Rear Strut Installation

To replace the rear struts on a Taurus you will need to remove two sets of bolts/nuts. The first one

being located on the top of the strut which can be accessed from underneath the rear speaker cover inside the vehicle.

Once the nut has been removed the next bolt to remove is located on the bottom of the strut connected to the rear hub.

Once the bottom bolt has been removed the strut can be lowered out of the vehicle and removed. The new part

can then be placed in the vehicle the same way that the old one had been removed. When tightening the bolts back up make

sure to torque the top nut to 22 ft-lbs. The lower bolt on the strut must be tightened to 59 ft-lbs.

To replace the rear struts on a Taurus you will need to remove two sets of bolts/nuts. The first one

being located on the top of the strut which can be accessed from underneath the rear speaker cover inside the vehicle.

Once the nut has been removed the next bolt to remove is located on the bottom of the strut connected to the rear hub.

Once the bottom bolt has been removed the strut can be lowered out of the vehicle and removed. The new part

can then be placed in the vehicle the same way that the old one had been removed. When tightening the bolts back up make

sure to torque the top nut to 22 ft-lbs. The lower bolt on the strut must be tightened to 59 ft-lbs.

Taurus Rear Strut Upper Nut Torque Specs : 22 ft-lbs

Taurus Rear Strut Lower Bolt Torque Specs : 59 ft-lbs

| Rear Suspension Torque Spec | |

|---|---|

| Control Arm Bolts Torque Spec | 75 ft-lbs |

| Swaybar to Strut Torque Specs | 10 ft-lbs |

| Swaybar to Frame Torque Spec | 30 ft-lbs |

| Shock Upper Nut Torque Spec | 22 ft-lbs |

| Shock Lower Nut Torque Spec | 59 ft-lbs |