1998 - 2012 Crown Victoria 4.6L Torque Specs

2004 Crown Victoria Front End Torque Specs

Click the area you are looking for!

Crown Victoria 4.6L Repair Information

Crown Victoria 4.6L Engine Repair Information

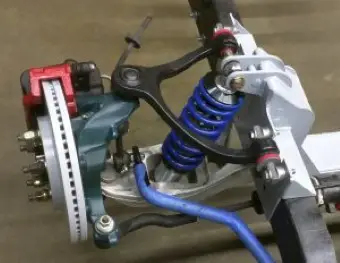

Here you can find information regarding the assembly of the Crown Vic front end. In this guide we will cover the essential repairs for the front end of this vehicle. Included within these repairs is the inner and outer tie rod removal and change, the front wheel hubs installation, ball joint removal and installation, the upper and lower control arms, and the front shock installation. Along with the repair procedures we also include the corresponding bolt torque specs for each fastener involved. These guides are intended to assist in each procedure to help diyers with the job.

Crown Vic Tie Rod Change/Removal

Crown Victoria Outer Tie Rod Torque Spec : 60 ft-lbs

Crown Victoria Inner Tie Rod Torque Spec : 75 ft-lbs

Front Wheel Hub Installation

Crown Victoria Front Wheel Hub Torque Spec : 75 ft-lbs

Crown Victoria Lugnuts Torque Spec : 95 ft-lbs

Front Ball Joints Installation

Crown Victoria Front Lower Ball Joint Torque Spec : 110 ft-lbs

Crown Victoria Front Upper Ball Joint Torque Spec : 110 ft-lbs

Front Control arms Installation

Lower Control Arm

The front control arms consist of two portions per side, these are the upper and lower control arms. I'm going to start from the lower control arm and then move to the upper one. There are four main fasteners that hold in the lower control arm. The first one being the largest is in the back and consists of a bolt that goes through the rear or most inwards part of the arm. The bolt hole will need to be lined up with the hole in the frame and then you can fit the bolt through and install the nut. The nut torques to 166 ft-lbs and can be secured further by using blue loctite when installing. The next fastener that is also positioned further into the vehicle is the 3 15mm bolts that hold up the other end of the control arm. These bolts can be torqued to 66 ft-lbs and the single bolt that holds the rubber mount to the control arm can be torqued to 129 ft-lbs if it is a 21mm nut and 150 ft-lbs if it is a 24mm nut. The next main fastener is the bolt that holds the shock to the control arm. This bolt can be installed using blue loctite and will need to be torqued to 166 ft-lbs. The final step is installing the lower ball joint into the spindle, this nut can be torqued to 110 ft-lbs.

Upper Control Arm

The next control arm is refered to the upper control arm. The role of this part is to hold the spindle and wheel assembly aligned properly. The part consists of 3 fasteners, two being bolts in the back of the part and one being a ball joint in the front or closest area of the part. The two bolts in the back will need to be torqued to 110 ft-lbs. The last fastener is the nut that holds the upper ball joint onto the spindle. This nut will also need to be torqued to 110 ft-lbs. All bolts can be installed with some blue loctite to ensure that none of them come loose while driving the vehicle.

Crown Victoria Lower Arm Crossmember Bolt Torque Spec : 166 ft-lbs

Crown Victoria Lower Arm Frame Bolt Torque Spec : 66 ft-lbs

Crown Victoria Lower Arm Bushing Nut Torque Spec (21mm): 129 ft-lbs

Crown Victoria Lower Arm Bushing Nut Torque Spec (24mm): 150 ft-lbs

Crown Victoria Upper Arm Bolts Torque Spec : 120 ft-lbs

Front Shocks installation

Crown Victoria Front Shock Upper Nut Torque Spec : 37 ft-lbs

Crown Victoria Front Shock Lower Bolt Torque Spec : 166 ft-lbs

Front swaybar Installation

Crown Victoria Front Swaybar Bracket Torque Spec : 46 ft-lbs

Crown Victoria Front Swaybar Endlinks Torque Spec : 46 ft-lbs

Steering Gear Installation

Crown Victoria Steering Gear Studs Torque Spec : 13 ft-lbs

Crown Victoria Steering Gear Nut Torque Spec : 75 ft-lbs

| Front Steering Torque Specs | |

|---|---|

| Outer Tie Rod Torque Spec | 60 ft-lbs |

| Inner Tie Rod Torque Spec | 75 ft-lbs |

| Steering Box Studs Torque Specs | 13 ft-lbs |

| Steering Box Nuts Torque Spec | 75 ft-lbs |

| Front Wheel Hub / Knuckle | |

| Wheel Hub Bolt Torque Specs | 75 ft-lbs |

| Brake Caliper Bracket Torque Spec | 120 ft-lbs |

| Wheel Axle Nut Torque Spec | 220 ft-lbs |

| Swaybar Mount Torque Spec | 46 ft-lbs |

| Swaybar Endlink Torque Spec | 46 ft-lbs |

| Control Arms Torque Specs | |

| Lower Ball Joint Torque Spec | 110 ft-lbs |

| Upper Ball Joint Torque Spec | 110 ft-lbs |

| Lower Arm Crossmember Bolt | 166 ft-lbs |

| Lower Arm Frame Bolts | 66 ft-lbs |

| Lower Arm Bushing Nut (21 mm) | 129 ft-lbs |

| Lower Arm Bushing Nut (24 mm) | 150 ft-lbs |

| Upper Arm Bolts Torque Spec | 120 ft-lbs |

| Front Shock and Extra Knuckle Torques | |

| Upper Shock Bolt Torque Spec | 37 ft-lbs |

| Lower Shock Bolt Torque Spec | 166 ft-lbs |

| Stabilizer Frame Bolt Torque Spec | 52 ft-lbs |

| Stabilizer Link Torque Spec | 40 ft-lbs |

| Idler Frame Bolt Torques | 60 ft-lbs |

| Idler Drag Link Torques | 55 ft-lbs |